Decommissioning

Bury your Unprofitable Pipe with the Least Cost

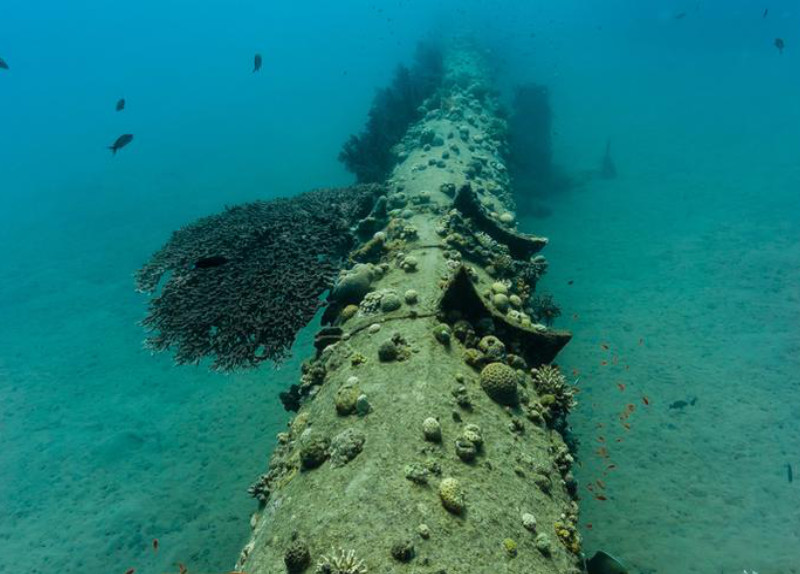

When pipelines reach the end of their service life a decommissioning process is required. Regulatory requirements can differ drastically depending on jurisdiction. There is high variability in the required method and verification process of hydrocarbon removal, hydrotesting, and the chemical compositions of suspension fluids. Most generally, a series of deoiling, dewatering, and/or debris removal gels displaced by elastomer pigs can prepare a pipeline's surface for flushing. A gelled inhibitor treatment can then be ran preparing the pipeline for flooding, plugging if determined necessary, and abandonment. In the event that an abandoned or out-of-service pipeline is being reintroduced into a pipeline system, these same steps can be taken to prepare the pipeline for recommissioning and ultimately the introduction of its transported fluid.

Product List